Introduction

In the world of manufacturing, technological innovations have consistently played a pivotal role in driving efficiency, precision, and competitiveness. Among the many breakthroughs that have revolutionized this industry, lasers have emerged as a shining star, transforming the landscape of production processes. Over the last few decades, lasers in manufacturing have seen remarkable growth, bringing about a multitude of benefits. In this blog post, we’ll delve into the dynamic world of lasers and explore how they have become an integral part of modern manufacturing. Innovative Laser Safety is here for you and your team for all your laser safety needs.

Laser Types and Manufacturing Applications:

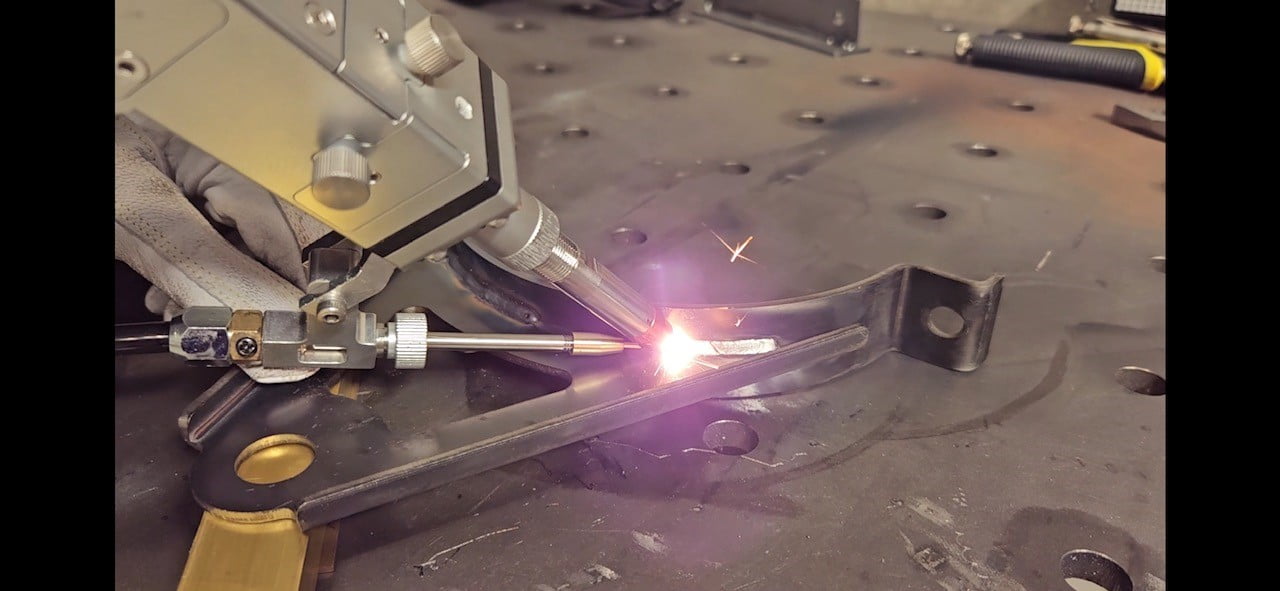

- Cutting and Welding: One of the most prevalent uses of lasers in manufacturing is cutting and welding. Lasers, such as carbon dioxide (CO2) and fiber lasers, are highly efficient at precisely cutting or welding various materials, including metals, plastics, and ceramics. This accuracy reduces waste, increases productivity, and ensures consistent quality.

- Marking and Engraving: Lasers are widely employed for marking and engraving components, products, and packaging materials. The non-contact nature of laser marking ensures that the surface remains intact, making it ideal for intricate designs, serial numbers, and barcodes.

- Additive Manufacturing: In the realm of 3D printing and additive manufacturing, lasers have brought about significant advancements. Selective Laser Sintering (SLS) and Stereolithography (SLA) are just two examples of additive manufacturing processes that rely on lasers to fuse or solidify materials layer by layer.

- Heat Treatment: Lasers are used for heat treatment processes to modify the properties of materials like metals. This method can enhance the hardness, toughness, or corrosion resistance of components, making them suitable for various industrial applications.

- Micro-Machining: Lasers have enabled manufacturers to produce highly precise and intricate micro-parts. Micromachining, which utilizes ultra-short pulse lasers, is indispensable in electronics, medical device manufacturing, and more.

The Advantages of Laser Technology in Manufacturing

- Precision: Lasers offer unparalleled precision, enabling manufacturers to cut, weld, or engrave with incredible accuracy. This precision reduces material waste and rework, resulting in cost savings.

- Speed: Lasers operate at high speeds, which significantly increases the throughput of manufacturing processes. Faster production times can lead to quicker turnaround for customers and improved productivity.

- Flexibility: Laser systems can adapt to a variety of materials and geometries, making them versatile for different manufacturing needs. This adaptability enhances efficiency and the ability to handle diverse production requirements.

- Minimal Thermal Impact: Laser processes often have minimal thermal impact on materials, reducing the risk of deformation or other heat-related issues. This is crucial for sensitive components and heat-sensitive materials.

- Automation: The integration of lasers into manufacturing processes can be easily automated, further enhancing efficiency and reducing labor costs.

The Future of Lasers in Manufacturing:

As technology continues to advance, the future of lasers in manufacturing holds exciting possibilities. We can expect to see even more intricate and high-precision applications, a broader range of materials that can be processed with lasers, and the integration of lasers with other cutting-edge technologies like artificial intelligence for smarter and more efficient manufacturing processes.

Conclusion

In conclusion, the growth of lasers in manufacturing is a testament to human ingenuity and the pursuit of precision and efficiency. From precision cutting and marking to additive manufacturing and micromachining, lasers have found their place in a wide range of applications. As technology continues to evolve, we can anticipate even greater contributions to the manufacturing industry, ultimately benefiting both manufacturers and consumers alike.

The illumination brought by lasers to manufacturing processes is not only a revolution but a promise of a brighter, more efficient future for the industry. Don’t forget to reach out to us at Innovative Laser Safety for any questions.